Information contained above this line was not contributed by the owner

of this site

UNORTHODOX UNDERDRIVE PULLEY INSTALLATION NIGHTMARE

Unorthodox Main Underdrive Pulley

|

One of our members was victimized by an Unorthodox underdrive pulley

installation gone awry. Before getting into the gory details it should

be said upfront that there is nothing at all wrong with the Unorthodox

pulley itself - in fact it is a very nice piece, It's light, machined from

billet aluminum and has a nice finish. It performs exactly as advertised.

The problem is it is VERY VERY difficult to install correctly. Even the

professionals have had their fair share of problems. And the only indication

of an incorrect installation is a slight wobble in the pulley when the

engine is running. Then after a few thousand miles of use all hell breaks

loose. Read on if you dare!

|

Our victim installed the Unorthodox pulley and had the telltale wobble

and decided it was worth the effort to see if this wobble was truly an

issue. But first a little background. To install the Unorthodox pulley

the old pulley must be removed. This consists of the pulley itself and

the hub the pulley is bolted to. This hub is held on the end of the eccentric

shaft by one big bolt. This bolt not only holds on the hub but also holds

in place a whole series of bearings, races, and oil pump hardware (gears

and chains). What happens is when this big pulley hub bolt is removed,

tension is lost that holds all this hardware in place. The eccentric shaft

bearings then drop out of position so when you go to bolt it all back together

and turn the engine over... hey presto one big chewed up mess. Sure the

engine will run, but it won't run for long.

So what to do? Read on......

First you need to take all your patience and remove everything from

the front of the engine. Also, you need to remove the oil pan to do it

correctly. To give you an idea of the extent of work needed to fix this

mess the workshop manual it tells you the motor needs to be removed! However,

our victim successfully performed the work with the engine in the car.

Disclaimer: This is NOT an all inclusive instruction

- merely a guide to provide insight as to the severity of damage that can

occur.

Ok Lets begin....remove the following:

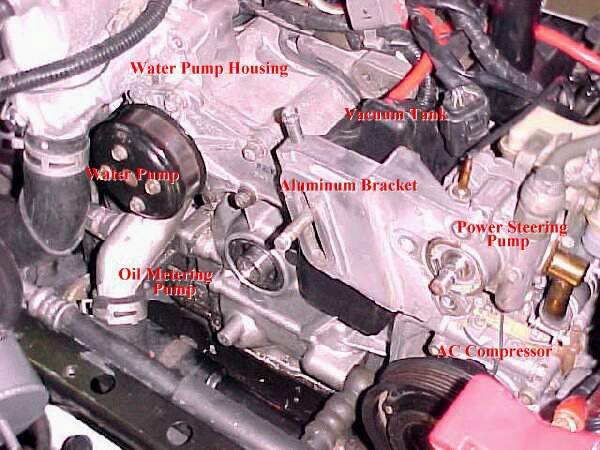

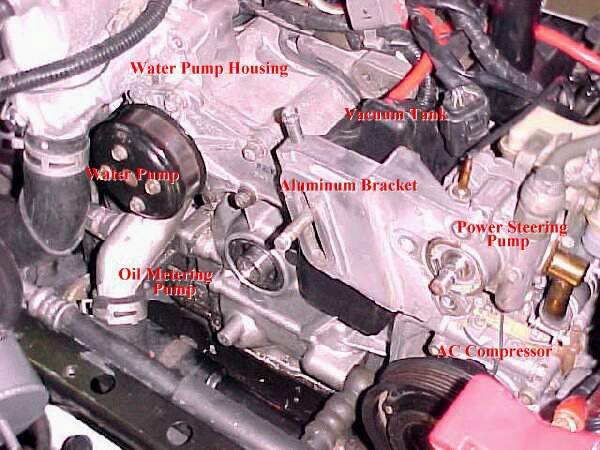

Aircleaner and all hosing from the intercooler and piping, intercooler,

alternator, water pump housing, oil metering pump/harness/oil lines, power

steering pump, ac compressor, aluminum bracket for the above mentioned,

oil cooler line from front cover, vacuum tank.

Water pump housing removed - "front cover" is center of picture

|

Next move on to the front cover:

remove the oil pan bolts to front cover

and remove the oil pan

(this requires dropping the engine sub frame! Scared yet?)

Remove all the remaining bolts on the front cover

and slide it off

|

Then remove oil pump gear locking tab and nut. Remove oil metering

pump drive gear from eccentric shaft (slides off). There is a tiny key

that goes to the oil pump shaft...DO NOT LOOSE IT!! (this sometimes has

to be filed just a bit to get it in the key way slot such that the oil

pump gear will fit correctly. Remove counter weight on eccentric shaft

(slides off) [Sorry no pictures of this stuff]

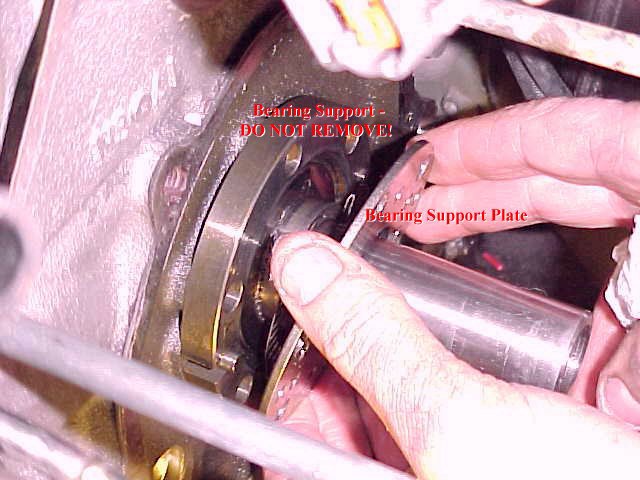

Now we get to the heart of the problem:

Remove the needle bearing (which has probably been destroyed) and the

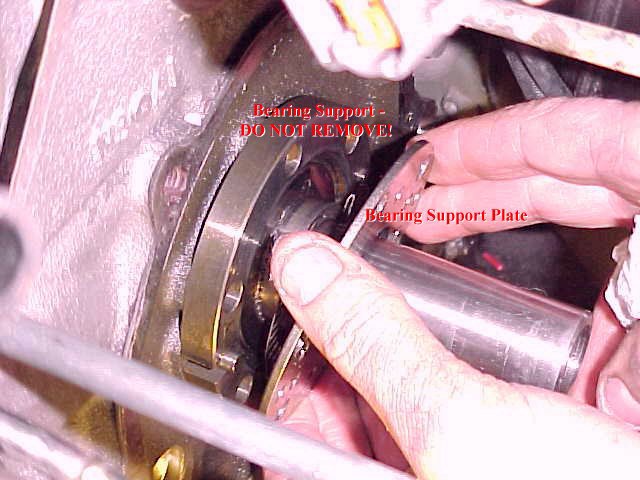

front bearing support for the engine with six bolts in it. Remove the bolts.

Is that a needle bearing in there? Visible through holes

in the front bearing support. Notice how the bearing has "dropped down."

Remove thin plate only (which has also probably destroyed) WARNING:

DO NOT REMOVE THE WHOLE BEARING SUPPORT AS THE ROTOR WILL FALL OUT OF PLACE

AND THE ENGINE WILL HAVE TO BE COMPLETELY TORN DOWN TO REPAIR

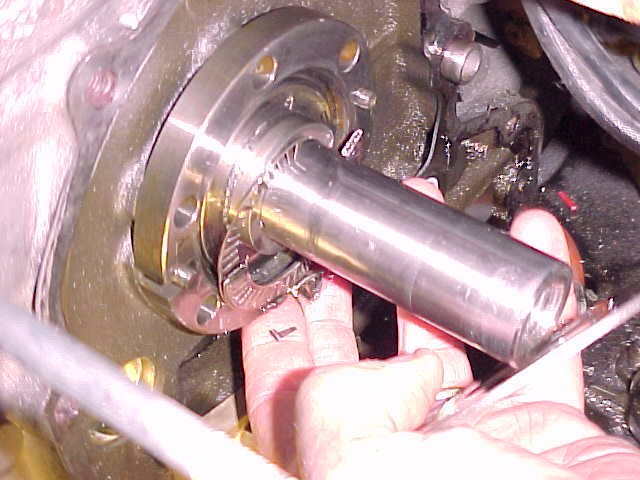

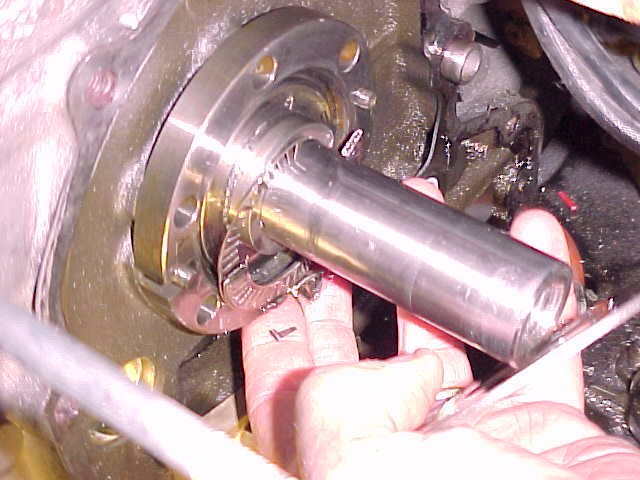

There is then the second needle bearing (also probably destroyed)

On the eccentric shaft is a small collar that the needle bearings ride

on (again this will probably be destroyed - are getting the point yet?)

Note: If needed to be replaced you have to mic it for correct size.

There are over ten different sizes available. It is imperative that the

right one is reinstalled. Ok so here is what we found:

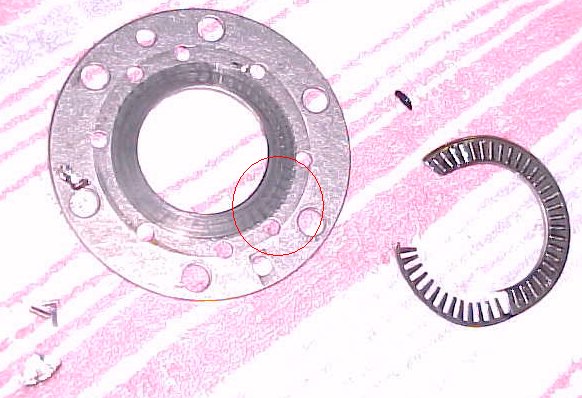

Removal of front bearing support plate.

Remains of inner needle bearing.

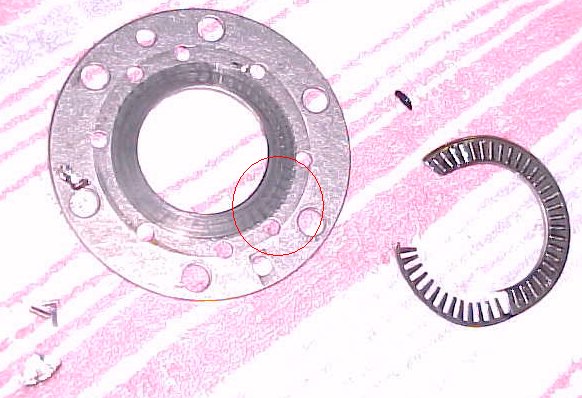

Support bearing plate - notice chatter marks (circled)

and few remaining bearings.

Where did all the bearings go? Most were fished out of the oil pan

but it is presumed that some were simply ground up and will eventually

be caught by the oil filter - one hopes.

Ok, now that the bits and pieces are strewn all over your garage

and you are wondering how the hell you are going to get it all back together

its time to begin :-)

Once you have all your new parts (about $130.00 worth), install

in the following order: Most importantly is to slide the small collar on

first, all the way against the bearing support Install the needle bearing

with vaseline.

Then the plate with the bolts (loctite on the bolts) Then the other

needle bearing. Counter weight. Oil pump chain and gear and the the drive

gear for the metering pump. Note: when the gasket for the front cover is

reinstalled there is also a plastic ring and o-ring for the oil passage

between the front cover and engine. Attach this to front of the engine

with Vaseline, making sure it stays or you will loose all oil pressure.

Yikes!

Once you got the front cover on the first thing to do is install

the pulley and bolt. Torque it down and then install all the rest in reverse

order.

Whew!

Any Questions?

"THE TRACK!"

TRIPLE-R | THE WORLD OF THE RX-7

MAIN PAGE

This page last updated April 17, 2001

rotorphiles have visited this page since April 17, 2001

rotorphiles have visited this page since April 17, 2001

If you would like to contact the 7-Up Club and converse about

our experiences:

please feel

free to send an e-mail to rotarypower@rx-7.net

please feel

free to send an e-mail to rotarypower@rx-7.net

Disclaimer: All images contained on this page are

the sole property of C. Regan or were collected from the public domain,

unless otherwise indicated. If any image contained on this page is considered

private property please contact Christopher

Regan.Webcounter supplied courtesy of