Information contained above this line was not

contributed by the owner of this site

THE TRIPLE-R ENGINE TORQUE BRACE

The Original Triple-R Engine Torque Brace

Most people when they first see the brace (aka power bar) they normally ask, "what the heck is that?"

and "what is it supposed to do?" My answer typically goes like this: "An engine brace,"

and "Well, actually, I believe it does...."

Bear with me. Looking for some unique performance enhancements,

while browsing through some Japanese websites, I happened upon the Knightsports

Power Bar. This is was new product that I believe Knightsports released in the summer of 1998.

I also saw many Japanese car owner sites showing pictures of similar such items. Some using

a solid bar and some using a damper (an adapted motorcycle steering damper).

At the time I had personally not seen one on any other car.

After doing some exploration I found that the Knightsports Power Bar would set you back about $380!

Heck, I bet I could make my own. And so I did. I designed the brace using a solid modeling program

and from there fabricated a prototype brace using hardware from a racing supplier and some aluminum stock I had

leftover from other projects.

I used this prototype with great succes for almost two year both on the street and on the track.

My theory on its purpose are that it minimizes engine windup during rapid throttle

applications. This not only will increase throttle response but also add to the longevity

of the OE lower motor mounts which are somewhat prone to failure. Additionally because there is less

movement in the drivetrain the shifter postion is less prone to movement which commonly

results in missed shifts and subsequent synchro damage.

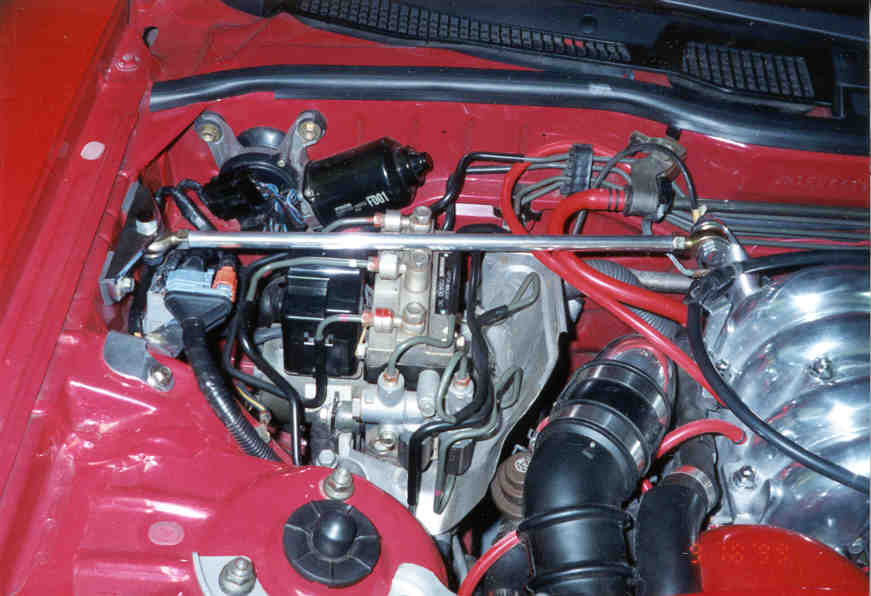

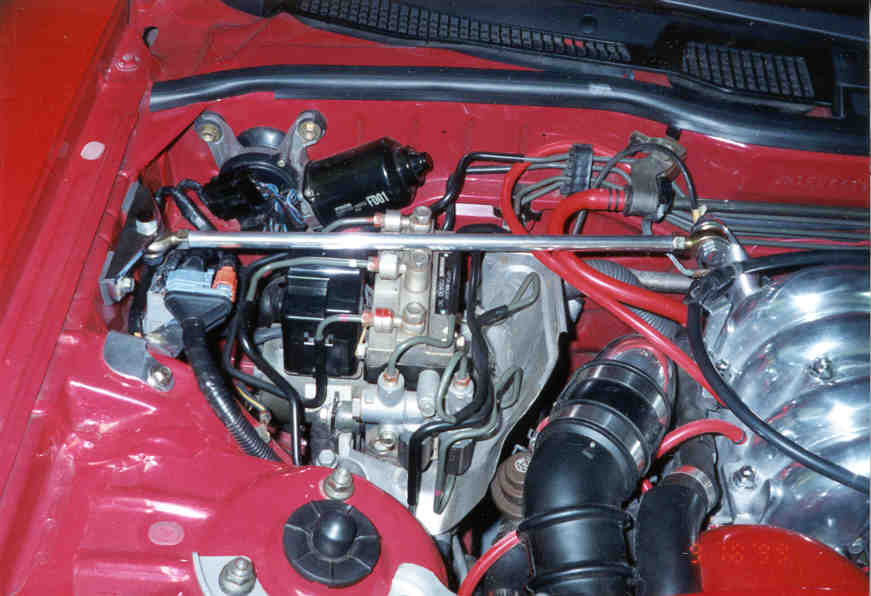

Some issues that were addressed were clearing the ABS pump

(Japanese powerbars need only clear the brake booster)

and minimization of vibration and noise to the chassis. Issue one wasn't really an issue

as it cleared fine and issue two has been somewhat addressed by using some high density

impact foam (prototype only - rubber for the production units) between the chassis mounting

bracket and the fender wall. No other modifications to the car were made.

The bracket to the upper intake manifold (UIM) uses the engine hoist bolt holes and there

are two factory prethreaded bolt holes in the fender wall for the chassis bracket. The bar itself is adjustable

for length by loosening the jam nuts and turning the bar by hand. Changing the length of the bar

preloads the engine mounts in either direction as desired.

My only concern was the potential for excessive loads to be imparted to the manifold which might prematurely degrade the

gasket interfaces to the lower extension manifold. However, after two years of track and street use there has been no indication

of any problem. In addition similar devices have been around for 2nd generation RX-7's for ages with no real problems

that I could find.

Triple R Engine Torque Brace Mass Production

Triple R Engine Torque Brace Mass Production

The final Triple-R Engine Torque Brace from the first prodution run.

The final Triple-R Engine Torque Brace from the first prodution run.

Well it seems my design, of which I have helped many replicate, has reached such a demand that a

production run was undertaken with the assistance of Phillip Keezer. The production unit was

produced using a CNC machining process for the chassis fender bracket and the UIM bracket was

laser cut thus holding the tolerences to much higher level than what I could produce by myself.

laser cut UIM bracket prototype

laser cut UIM bracket prototype

The finished production model comes with all the necessary mounting

hardware and instructions. Pictured below are details of my own production model from the first run of 40 units.

Note: Some minor differences may exist in hardware due to availability but all function in the same manner.

The purchased items do NOT come polished but with a high quality machined surface. If interested in one of these devices

they can be purchased through the RX-7 Store Look under "Engine Parts"

TRIPLE-R MAIN PAGE

GENERAL OVERVIEW |

THE HEART OF THE BEAST |

STOPPING AND TURNING |

THE COMFORT ZONE

7-UP CLUB MAIN

OUR "LOCAL7" COMMUNITY |

THE WORLD OF THE RX-7

This page last updated April 17, 2001

rotorphiles have visited this page since April 17, 2001

rotorphiles have visited this page since April 17, 2001

If you would like to contact me and converse about my experiences with my 7:

please feel free to send

an e-mail to

rotarypower@rx-7.net

please feel free to send

an e-mail to

rotarypower@rx-7.net

Disclaimer: All images contained on this page are the

sole property of C. Regan or were collected from the public domain,

unless otherwise indicated. If any image contained on this

page is considered private property please contact

Christopher Regan.

Webcounter supplied courtesy of