The whole system: Mandeville brakes, Koni shocks w/Ground

Control coilovers, CWC CF ducts, and the Tripoint Swaybar w/CWC billet

sway bar mounts

An installed CWC Kevlar Reinforced Carbon Fiber Duct |

I must begin by saying the CWC Kevlar Reinforced Carbon Fiber Duct have been very well crafted and literally weigh next to nothing. By my estimate only several ounces a side. I thought the box was empty when I received it in the mail! Essentially the duct consists of a scoop bonded to a backing plate that replaces the OE metal splash shield/duct. The OE "duct" is somewhat ineffective in directly air to the rotor because it's vestigial duct does not extend outside the area enclosed by the wheel itself. Of the 5 of us that purchased the CWC ducts we can attest to the fact that they did fit all our brake setup with some minor fitment. These brake setups included, the stock brakes, Mandeville 13" rotors with OE calipers, M2 Wilwood 6 piston caliper with 13" rotors, and the Mov-it Porsche "Big-Reds" with 12.75" rotors. The backing plates for the big brake setups were cut down to fit more effectively inside the rotor eye, whereas the backing plates for the stock rotors were designed simply to mount flush with the rear face of the stock rotor. |

|---|

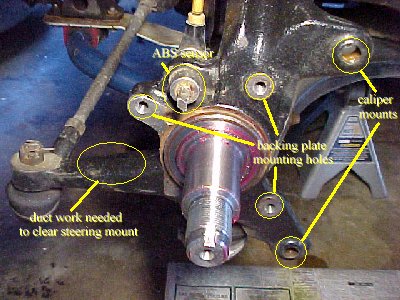

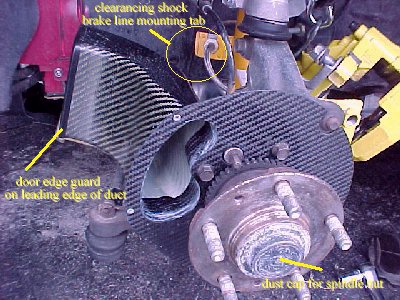

| Installation requires removal of the brake caliper (you can hang it from the suspension arm using a large "S" hook to the hard line on the back of the caliper. Do not let it hang by the brake line!), brake rotor, and the wheel hub carrier and bearing assembly (which also carries the ABS sensor trigger wheel). This to facilitate removal of the OE splash shield and installation of the CWC duct. The hub carrier is removed by popping off the ducts cap (don't bend it!), bending out the stake on the spindle nut (make sure you re-stake the nut when reinstalling), and removing the spindle nut (1 3/8" socket). Don't worry about the bearings as they are a sealed unit and will come off with the hub. The ducts are mounted using the 3 OE mounting bolts. Now for the fitment issues. Some may need to open up the mounting holes and ABS sensor hole in the CWC backing plate to allow snug fitment of the backing plate to the spindle carrier. This can be done carefully using an ultrafine file. In my case I also needed to remove some material to allow the duct to sit correctly over the steering arm mount. Additionally I added spacer washers between the backing plate and the hub to get the backing plate to seal tighter to the eye of the rotor. Also as added protection, although the kevlar is very tough I used door edge guard on the leading edge of the duct to protect the unfinished carbon fiber. |

backing plate mounting points and steering arm that might need work to clear duct |

|---|

My installed duct with minor work needed to fully clear brake line tab |

CWC duct installed with OE brakes |

|---|